We know the consequences of climate change. We know the causes, too. We even know what can be done to address it. What we don’t know is how best to shift into gear to get there in time. It’s why RBC Economics and Thought Leadership set out on a year-long research project to map out some of the necessary pathways for Canada to get to Net Zero. That’s the state when we take as much or more carbon dioxide, methane and other greenhouse gases out of the air as we put into it. And we need to get to that state by 2050, or sooner, to avoid the irreversible consequences of climate change.

At RBC, we’re committed to Net Zero in our own operations and lending portfolios. We’re working with governments, regulators, clients, environmental groups and the global financial sector to understand what’s needed from each of us—and to share those insights as widely as we can, because we believe a shared understanding of the challenges can lead us to better solutions for all. We undertook this research to inform and inspire those conversations, and welcome you to join the conversation and learn more through our new RBC Climate Hub. The more we can listen and learn, and share the same facts, the better our chances of using Canadian resources and ingenuity to solve perhaps the greatest challenge of our time and achieve Net Zero, together.

![]()

Canada has a math challenge.

When it comes to greenhouse gas emissions, Canadians account for a relatively large share of what the world produces. Although we’ve committed over the decades to cut those emissions, we’ve fallen short. We continue to consume conventional energy to cross our vast land and heat our homes, and allow methane to seep into the atmosphere to feed ourselves and much of the planet.

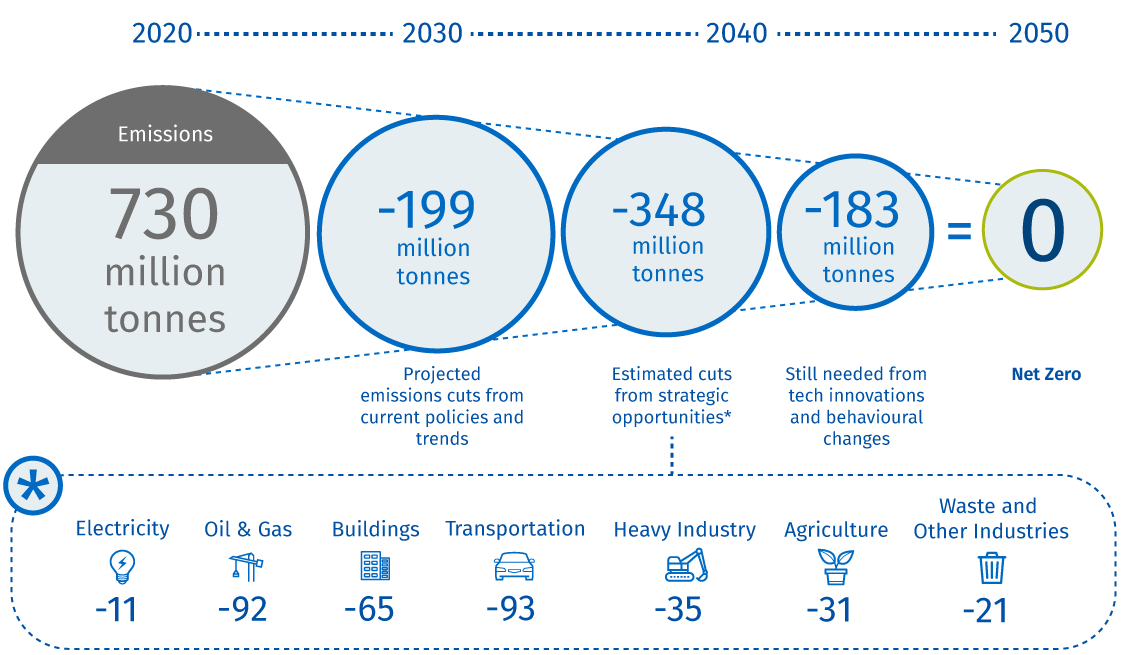

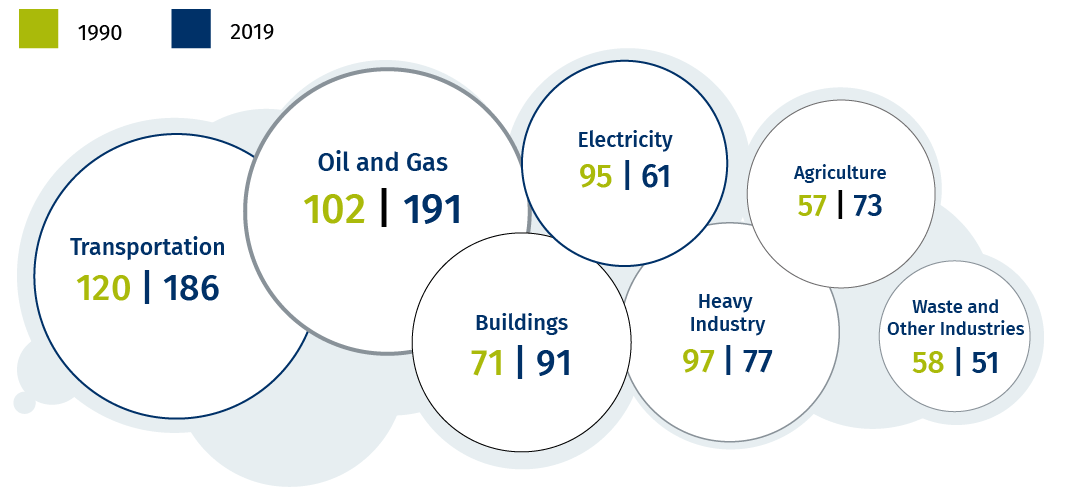

All told, we’re putting as much pollution into the atmosphere as we did a generation ago. We don’t have another generation to shift gears—not if we want to avoid the worst consequences of global warming. Canada emits roughly 730 million tonnes of carbon dioxide and equivalent greenhouse gases each year, making us the world’s 10th largest emitter. That number may seem small compared to the nearly 50 billion tonnes the world produces, notably from the U.S. and China. But it’s a lot more than the 602 million tonnes we generated in 1990, just before the world’s first Earth Summit.

Despite our best intentions, emissions have grown

Greenhouse gas emissions, million tonnes of CO2, equivalent

Source: Environment and Climate Change Canada, RBC Economics

To get on a more serious path to Net Zero, the federal government committed to getting Canada back to around 500 million tonnes by the end of this decade—and eliminating or offsetting the rest by 2050, using new technologies like electric vehicles, new heat sources for homes, and new processes to capture and store some of the emissions that we’ll continue to produce to power our planet.

This report aims to map out some of those pathways, as well as the investments and policies needed to achieve Net Zero. We use a range of established modelling on the emissions of major sectors, and the potential of breakthrough technologies, behavioural changes and improvements in industrial and agriculture processes. Our research aims to project out, over 30 years, what the estimated long-term costs and benefits could be, understanding that many uncertainties exist around climate, technology and behavioural trends and such forecasts will continue to evolve.

The amounts needed could be hefty: around $2 trillion in the next three decades. Based on our estimates, governments, businesses and communities would have to spend at least $60 billion a year to cut Canada’s emissions by 75% from current levels, which is about as far as we can get with current technologies. That’s a significant jump from the estimated $15 billion a year we currently spend. While those are large numbers, they’re also affordable, especially when measured against the economic returns of new technologies, products and even entire industries in which Canada can be a global leader. For context, Ontarians alone spend nearly $70 billion a year on healthcare, an essential national priority.

Nature can help, of course. Scientific forecasts for large-scale tree planting and forest management suggest such measures could sequester some 50 million tonnes annually by 20501, which covers one-tenth of what Canada will need to get to Net Zero. (Protecting Canada’s forests, wetlands and grasslands from being converted to other uses could prevent another 30 million tonnes of GHGs from being released annually.)

Then there’s technology. A nation of electric vehicles, solar-powered houses and hydrogen-fueled airplanes will help enormously, and the innovation spurred by more uptake of these technologies can cut their costs and the overall bill. But as the chart below illustrates, the best-case scenarios for these technologies might only get Canada three-quarters of the way to Net Zero. We’ll need many more inventions, and new habits, to help transform industries and lifestyles. The good news: Canadians, whether we’re developing resources, building technologies or serving a diverse world, are strong innovators, especially in the face of challenges like climate change.

One of our biggest challenges: we’ll need to roughly double our electricity supply to power a new fleet of EVs, and to heat and cool our homes, offices and schools. Canada has a head start, with a “green grid” fed by hydro, nuclear, wind and solar power. We also have plenty of lower-emissions natural gas to serve as a transition fuel, be it for heavy industry or big cities, as the economics and reliability of renewables improve. More capacity will be needed on each front, as well as historic investments in transmission lines and a new approach to how provinces manage the sector.

A national green grid can help power some of the country’s biggest emitters in cleaner, and cheaper, ways. Canada will also need to help our oil and gas producers, farmers, manufacturers and others working in carbon-heavy sectors, as they continue to develop their own pathways to Net Zero, and ensure that any transformation does not cause widespread economic hardship or social disruption. (We will have more to share on the costs of a disorderly transition in an upcoming report.)

A long-term commitment to carbon pricing, with steady and predictable increases, will help, by allowing investors, entrepreneurs and operators to allocate capital efficiently and effectively. So, too, will a regular, independent and transparent assessment of the impact of carbon pricing, and whether the 2030 target of $170 per tonne is optimal. Such an approach to pricing carbon, at significantly higher levels than today, could even shape new economic thinking for North America, if Canada and the U.S. work cooperatively on continental supply chains for green products like EVs and trade measures to better price the cost of important energy-intensive products like steel.

This journey will require new approaches to sustainable finance, if we’re to generate the $2 trillion needed to finance the transition. Overall, capital is not in short supply. Investible projects, with reasonable returns, are. What’s needed? An overhaul of industrial regulation and tax policy, and more government backstops, to offset the inherently risky frontier of clean technology, sustainable infrastructure and new consumer products. A lack of consistent and reliable policies continues to impede Canada’s ability to attract the sort of private capital needed to finance the transition.

And we’ll need people—a lot of them—to focus on the skills required to power the transition, install neighbourhood solar grids, maintain new EV fleets, and reform farming practices to ensure Canada’s ample soil is used more actively to absorb carbon from the atmosphere. Estimates suggest Canada will need to retrain 100,000 workers with new green skills, and add up to 200,000 more like them to the labour force as early as 2030.

The cost of inaction

While cutting emissions is costly, there’s a cost to doing nothing, too—one that will continue to climb the longer we postpone action.

Trend growth – or potential growth – reflects the long-run sustainable productive capacity of the economy. Actual growth fluctuates around this trend due to short run ‘cyclical’ factors. Trend growth is estimated based on trend labour supply growth and productivity.

The challenges are serious, but so are the opportunities. Canadians are proven energy innovators, including around nuclear, hydrogen-cell and oil and gas-extraction technologies. We can’t delay action as we wait for new technologies to arrive.

Policy changes will be essential. But first we’ll have to take a hard look at the areas in which Canada has the biggest emissions. In the section that follows, we explore those areas and how they can become pathways to Net Zero.

![]()

Achieving Net Zero requires us to adopt technologies that can facilitate the transition from fossil fuels to electricity, in an accelerated but orderly manner. Still, some economic activities aren’t in a position to be electrified at scale, at least in the short term: think air travel and cement making. We’ll continue to burn fossil fuels to make plastics and to generate the electricity to power all those greener technologies.

We identified six pathways to Net Zero, and while they’re not all-encompassing, they are among the most viable opportunities within reach. Four of them, explored later in this section, outline ways to cut emissions from buildings, transportation, industry, and agriculture. Even still, if we all drove electric cars and lived in solar-powered homes, rethought livestock management and captured more carbon from smokestacks, we’d still have emissions. Successfully reducing emissions from the electricity and oil and gas sectors are the two pathways most essential to fulfilling our Net Zero ambitions. We’ll start there.

![]()

From the wind turbines on the Cape Breton coast to the dams of the James Bay Project and glittering solar panels along Vancouver’s skyline, you can see the footprints of a major electricity producer just about anywhere in Canada. We enjoy arguably the world’s best supply mix, and are fortunate to be able to take reliable electricity for granted. The companies behind those supplies have helped shape Canadian history, and will help define our future.

To power a nation of EVs and electric grills, to heat our schools when it’s -30°C and cool our offices during prolonged heat waves, we’ll need to double the supply of green electricity—essentially, power from hydro, nuclear, wind and solar. That won’t be easy in populated areas, which can still rely on relatively cheap oil and gas, especially to meet demand surges. Wind and solar are the most affordable options but often hard to get to, as large-scale renewables projects need to be built around nature’s dictates—for instance, where the wind is strongest (like in Northern Ontario, Quebec and Newfoundland)2 and where the sun shines longest (like the southern Prairies). That’s why natural gas – a Canadian strength – will be needed for the foreseeable future.

A hydrogen-powered future has long been promised. The lightest of gases, hydrogen burns hot and can be used in place of fossil fuels in trucks, trains and industrial boilers. However, the way we currently make hydrogen is an emissions challenge: using steam to break methane into hydrogen and carbon generates nine kilograms of CO2 for every kilogram of hydrogen produced. Adding carbon capture to that process yields a cleaner product called “blue” hydrogen, which relies on natural gas and could become a greater export opportunity for Canada as new regulations and process improvements take hold. The purest form, “green” hydrogen, is produced by splitting water molecules with carbon-free electricity—but it’s very expensive. Lowering its cost would be a great start, along with infrastructure to deploy green hydrogen at scale, and commercialize fuel cells for trucks and other heavy vehicles.

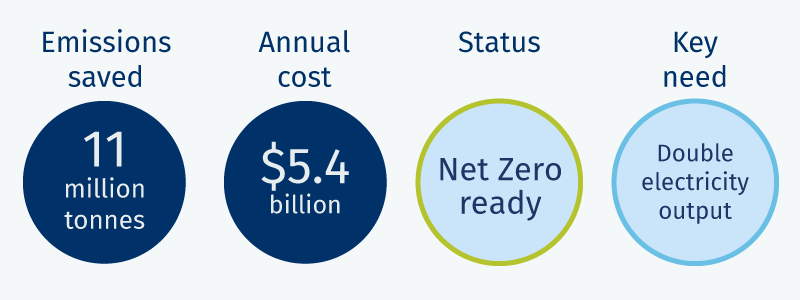

Canada is starting from an enviable position. As of 2019, 80% of the national grid was carbon-free. Compared with the U.K., our grid produces less than half the GHGs per unit of electricity, and a quarter compared with the U.S.

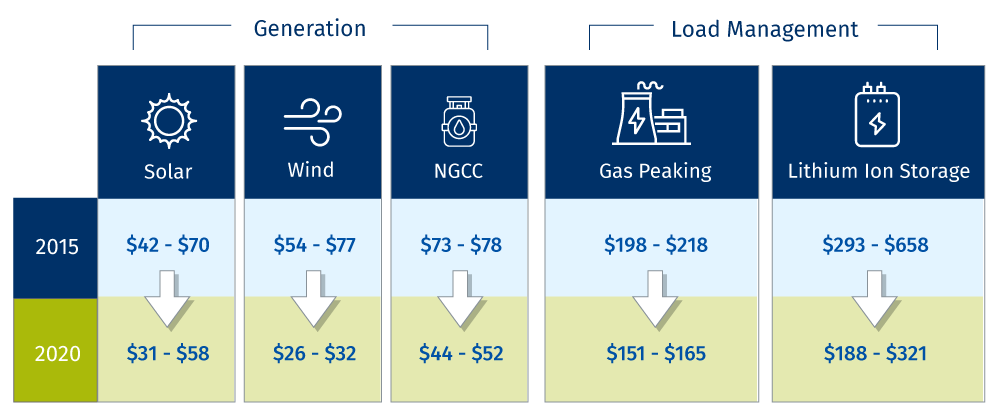

Efforts to phase out coal over the past decade, expected to be completed by 2030, have helped Canada cut carbon emissions from electricity generation. The continued use of nuclear energy helps, as have new additions of wind and solar power. Since 2010, almost all of the new capacity installed has come from renewables. That’s sped up because the cost of many zero-carbon electricity sources has declined: for new electricity plants, wind and solar generation are often 30% cheaper than natural gas. It’s a good example of something economists call “endogenous technology” – our choices today affect how technology development progresses.

In the near term, Canada’s best bet is to invest in more large-scale renewable energy. But as in every sector, any plan will involve making social and political choices. We’ll have to determine how much we’re willing to pay—collectively and individually—to accelerate the move away from fossil fuels.

Lower costs make wind and solar competitive, but not batteries

Levelized cost of electricity or storage, $US/MWh

Source: Lazard, RBC Economics

Handling the peaks

Another key challenge for renewables is that, unlike gas or coal power, they can’t be fired up at any time to meet demand, and they don’t produce electricity consistently when they’re on. Studies have shown that3 solar generation can fall by as much as a third in the winter and autumn, and wind farms produce more in the spring and winter. And that’s not taking into consideration climate variances between regions.

This so-called “intermittency” leads experts to suggest we’ll likely need some gas-fired power to manage periods when electricity is in highest demand, for example at dinnertime. The key question is whether it is cheaper to store electricity from renewables, cut peak demand with energy efficiency, or build new, simpler gas plants with carbon capture technology since many existing gas plants can’t respond to demand that quickly. More national modelling is urgently needed to work through these choices and help energy producers get on with the challenge.

Another way to improve the system is to better connect provincial grids. Right now, our grid is a hodgepodge of independent systems scattered throughout the country. Smoother connections could reduce the need for expensive storage by moving power from where it’s generated to where it’s needed.

Any transition from natural gas peaking plants will involve finding better ways to store energy for those rainy days. High-capacity batteries are expensive to use, but recent analysis from Lazard suggests costs at some projects are getting closer to natural gas peaking plants as technology improves.4 Pumping some of Canada’s abundant water into a reservoir during off-peak hours could make sense, too, but it’s mostly effective in mountainous areas.5 Future energy technologies, like small nuclear reactors and green hydrogen, could provide new solutions, but they’re a ways off from being commercialized. Storing electricity for the future will be the world’s critical energy challenge.

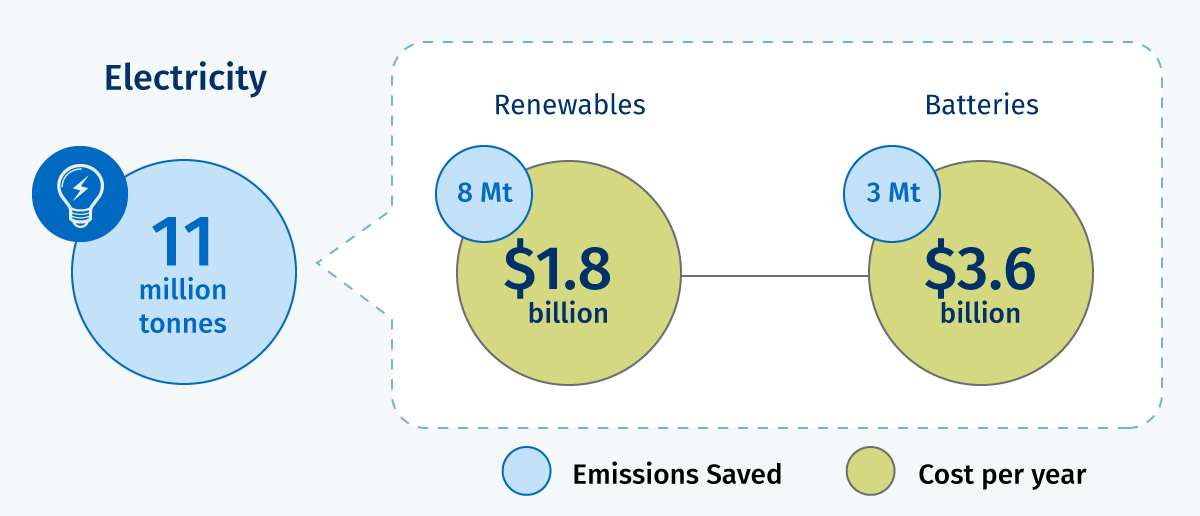

What will it cost?

As we look to increase electricity production, the source of all this new energy will be critical. Even in the existing grid, the costs of decarbonizing could run about $5.4 billion annually. Our ability to do that would be limited initially by the cost of building and deploying enough high-capacity batteries to store all the renewable energy we’ll need, though storage prices should drop as technology improves.6

Another question: will continued population growth require an even greater amount of electricity? Canada’s population is projected to rise about 30% to 50 million people in 2050. And many of the technologies we’ll use to cut emissions will require more electricity. Most estimates point to the system’s load increasing at least 100% by 2050.

General Fusion is developing the world’s first commercially viable fusion power plant, which will provide clean energy on demand, supplementing the intermittency of renewables. (In fusion energy, two light nuclei are combined to release large amounts of energy, producing four times more energy than nuclear fission.) The Burnaby, B.C. company’s 70%-scale demonstration plant in the U.K. will be complete in 2025. General Fusion has attracted some notable backers, including the U.K. government and Jeff Bezos. That could help the company as it competes against well-funded U.S. startups that are also racing to deploy fusion technology at scale.

Opus One Solutions’ platform allows utility companies to better manage and plan energy distribution as operating grids get more complex due to an increase in renewables. Singapore’s state-owned utility, SP Group, has contracted the Richmond Hill, Ont. firm to help optimize distribution and integrate more renewable energy into its grid. Opus One is also helping utilities in the U.K. and Australia develop more efficient and more flexible energy markets. While it offers a made-in-Canada solution, it will compete against giants like ABB, IBM, and Siemens in a competitive smart grid environment.

![]()

Nothing symbolizes Canada’s strengths, and challenges, as an energy power more than Alberta’s oil sands. At 165 billion barrels, Alberta’s proven reserves rank fourth in the world. The industry’s growth was made possible by homegrown innovation that allowed companies to vastly increase underground extraction of heavy crude. The province’s energy sector has been a major driver of economic growth, generating jobs, investment and almost a fifth of total exports, to the benefit of all Canadians.

Along with national pride, the oil sands continue to spark national and international debate. They’re Canada’s biggest single source of GHG emissions, at nearly 10% of the national total, and one-third of the 191 million tonnes of GHGs generated by the oil and gas sector in 2019. In 2021, to bring their net emissions to zero, the largest producers formed an alliance to invest billions in carbon-capture and sequestration, which will be critical to Canada’s overall success. But now governments need to match that commitment with additional investment and regulatory clearances to achieve Canada’s goals.

It’s the most important variable in our carbon equation, and won’t be easy to balance. Emissions from the energy sector have grown rapidly since in situ production took off in the early 2000s. About 80% of oil sands emissions now come from burning fossil fuels to make the steam used to bring bitumen to the surface and to use hydrogen to upgrade that bitumen into synthetic crude. More innovation will be needed to reduce those emissions, while also helping meet the world’s energy needs. Fortunately, the Canadian industry is a world leader in the science of heavy oil, and invested heavily in it before prices collapsed in 2015, and were hammered again in the early months of the pandemic.

The oil sands aren’t the only source of emissions in the sector, and because of Canada’s geography, a lot of energy is needed to get other forms of energy out of the ground and through pipelines to market. In conventional oil and gas production, two-thirds of emissions come from methane venting or leaks, as well as from naturally occurring CO2 in oil wells. Although methane – the main component of natural gas — causes about 80 times the warming of CO2 in the near-term, recent changes to federal and provincial regulations, along with more technology funding, have improved the outlook for Canadian gas as a global feedstock for blue hydrogen.

Such a step-by-step approach to emissions may be prudent, as we’ll need fossil fuels for years to come through the Net Zero transition. Demand for Canada’s oil, gas and plastics isn’t likely to wane significantly for a while, and could even rise for a time if U.S. demand stays strong. It will take years to phase out the internal combustion engine, transform natural gas-burning furnaces and develop alternatives for jet fuel. We also need petroleum to make petrochemicals and plastics for the foreseeable future. Curtailing oil production in Canada would put at risk our existing engineering advantages, especially if demand remains strong for some time, and could undermine our ability to study and develop other energy innovations, including green hydrogen, small nuclear reactors and electricity storage.

Another promising technology, direct air capture, envisages removing carbon straight out of ambient air. If it scales, that could also cut emissions from burning oil and gas. But for now, it’s not proven enough to rely on, and we must still move toward cleaner oil production, including capturing emissions as they’re produced.

Canada can benefit economically from maintaining production of crude and gas—but only if we act quickly to reduce the carbon intensity of Canadian production, and address carbon-intensive processes. Technological advances have already made energy production somewhat cleaner. Emissions per barrel in the oil sands have fallen 36% since 2000. Making Canada’s energy sector more efficient is critical to making our products more attractive as the rest of the world transitions.

In all parts of the energy system, reducing methane emissions should be a top priority, because the leaks cause significant warming and are among the cheapest reductions to make per tonne.

We must also ramp up use of carbon capture systems. Priority targets include stationary equipment at oil sands facilities and the methane reformers that produce hydrogen for upgrading bitumen. While carbon capture isn’t a perfect solution, it’s a known technology that can meaningfully stop GHGs from escaping into the atmosphere.

Carbon capture systems trap CO2 before it enters the atmosphere. There are various methods for doing this, but all basically end up compressing the trapped gas into a liquid and shipping it, usually by pipeline, to a storage facility. But the process has limitations. Carbon capture systems can be so costly that they make certain applications uneconomical. Another challenge is finding appropriate places to bury or trap the carbon so it doesn’t leak back into the air. A third issue is getting liquefied gases from a carbon capture facility to a place where they will be stored; that requires specialized, and sometimes very long, pipelines that further add to the cost and complexity of the whole effort.

Carbon capture can also help decrease emissions in off-grid parts of natural gas production. Where possible, we can electrify parts of the process that currently run on fossil fuels. Roughly the same goes for conventional oil production and oil refining.

A stumbling block to getting these projects off the ground is uncertainty: of the future carbon price, of regulatory approvals, and of community support. Another is finding long-term partners for projects. We’ll need to resolve these challenges to deploy CCUS at scale.

One avenue is to seek greater involvement from Indigenous communities. They have long fought for protecting the environment, a key goal of CCUS projects, and they have long-term interest in the land through which many CO2 pipelines would run, and which have the greatest capacity for CO2 storage. This makes them natural partners in these projects.

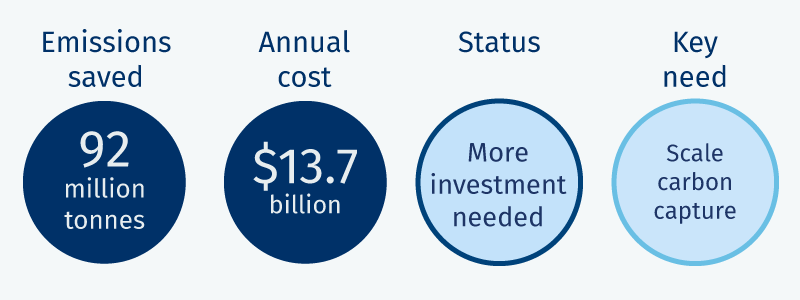

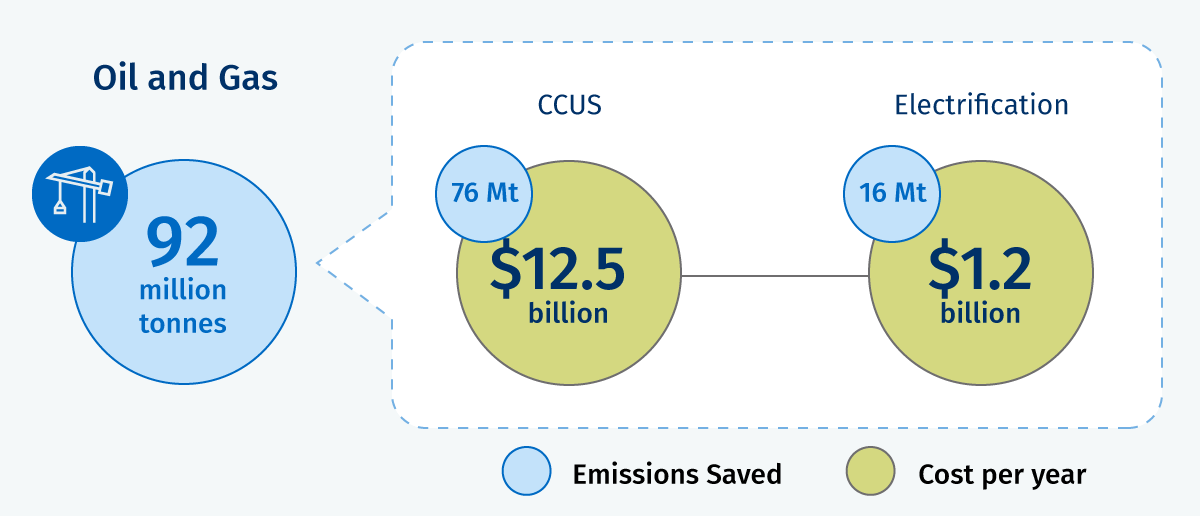

By 2030, the federal government expects oil and gas emissions to drop 53 megatonnes. The view after 2030 is far murkier because it’s difficult to predict how quickly current technologies will be adopted or new ones commercialized. Given what we know now, if $14 billion were invested by industry and government in green initiatives annually, 92 additional megatonnes could be eliminated in the oil and gas sector.

Carbon Engineering of Squamish, B.C. is a leader in direct air capture technology, which takes carbon dioxide directly from the atmosphere to then be sequestered or reused. Its facilities—one in Texas and another in Scotland—are slated to come online in 2024 and 2025, respectively. They’re each expected to remove 1 million metric tons of CO2 a year, or the equivalent of 40 million trees, all while being powered by renewable energy. (As of now, the world’s largest direct air capture facility is operated by Climeworks in Iceland and removes 4,000 metric tons of CO2 a year.) Direct air capture is a small, but important piece of the climate change equation, and it will need further development of carbon storage technologies to scale.

Carbonova’s unique chemical process uses carbon dioxide and methane to make carbon nanofibre—a cutting edge material with potential in numerous applications because it’s both stronger and lighter than steel. Carbon nanofibre’s proponents say it could be used to increase the storage capacity of lithium-ion batteries, while making paints and coatings more resistant and improving vehicle tires, among other uses. The Calgary-based company has received backing from prominent investors in Alberta’s oil patch and is building a semi-commercial reactor as the first step in scaling up production.

![]()

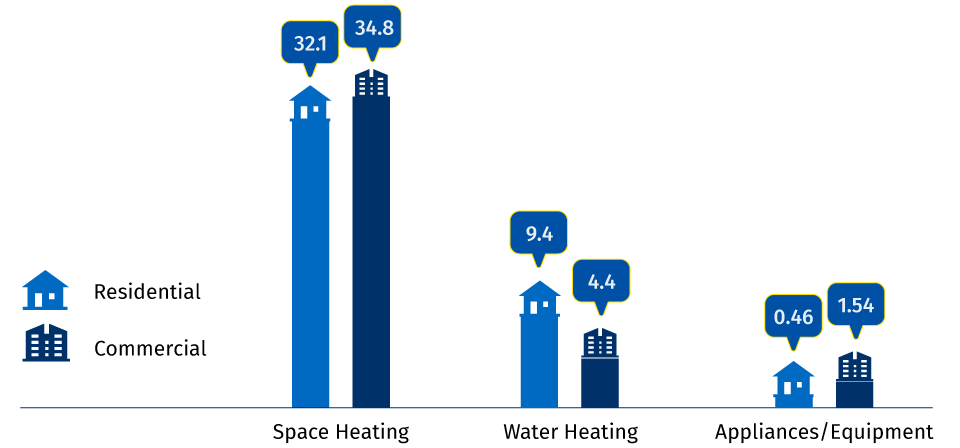

Buildings are Canada’s third-largest source of greenhouse gases. Space heating is by far the sector’s worst carbon culprit, accounting for about 75% of emissions in residential properties and 85% in commercial. Most of the remaining emissions come from water heating. Appliances and lighting contribute only a small share. And air conditioning is a relatively small line item because most AC units and systems are run in provinces with relatively clean electrical grids.

Heating buildings is Canada’s cold climate challenge

Greenhouse gas emissions (2020), Mt of CO2e

Source: National Resources Canada, Environment and Climate Change Canada, RBC Economics

An overarching problem is that much of the energy we use to regulate home and office temperatures is lost because of poor insulation, cracks and crevices in walls and out-of-date windows and doors. But voluntary programs aimed at making retrofits easier have so far failed to move the needle. For instance, a Toronto municipal program offering low-interest loans for home-energy improvements received less than 200 applications in five years.7

Efforts to encourage retrofits have fallen flat because of high upfront costs, a dearth of skilled tradespeople, and long pay-back periods for big upgrades. Even where retrofit programs make financial sense, there may be resistance because the work is disruptive and time-consuming. Landlords, too, don’t often see the energy cost savings from retrofits, which accrue to tenants.

Here’s the good news: total decarbonization is possible with current technologies. Indeed, efforts to reduce Canadian buildings’ carbon footprint are accelerating. Emissions per square metre have fallen with the introduction of more efficient appliances, retrofits and better building codes. Residential buildings have made more progress than commercial since 2000, at about 25% compared with 7%.

Phasing out fossil fuel-burning systems in favour of electric power will be key. Many parts of Canada already use electrical heat and hot water systems, but they can be expensive—especially so for building owners who switch over without first retrofitting their buildings.

One promising solution is the heat pump, a relatively new technology that moves heat from the outside air, water or ground and transfers it for use inside. It can also run in reverse. Heat pumps convert to heat much more efficiently than furnaces or boilers. As the technology behind them improves, overall utility costs should decrease in buildings with a solid retrofit plan.

Adoption of heat pumps has been slowed by high costs and also because many homeowners simply don’t know they’re an option. Another problem, at least for now, is that existing heat pumps are less efficient when temperatures dip below -15°C, so dwellings in the coldest parts of the country will need backup heat sources in the coldest periods.

Climate change has focused attention on communal alternatives to traditional on-site heating and cooling systems. Often called district energy systems, they distribute heat or cold air to multiple locations from a single source. In downtown Toronto, more than 180 buildings are connected to a shared cooling network that harnesses the cold temperatures of the water deep in Lake Ontario. District energy systems provide economies of scale, free up space in connected buildings and reduce emissions. Put another way, they spread the high cost of low-carbon systems over many users, making them feasible for more buildings. These systems are harder to incorporate into existing communities, but could suit places undergoing rapid population growth.

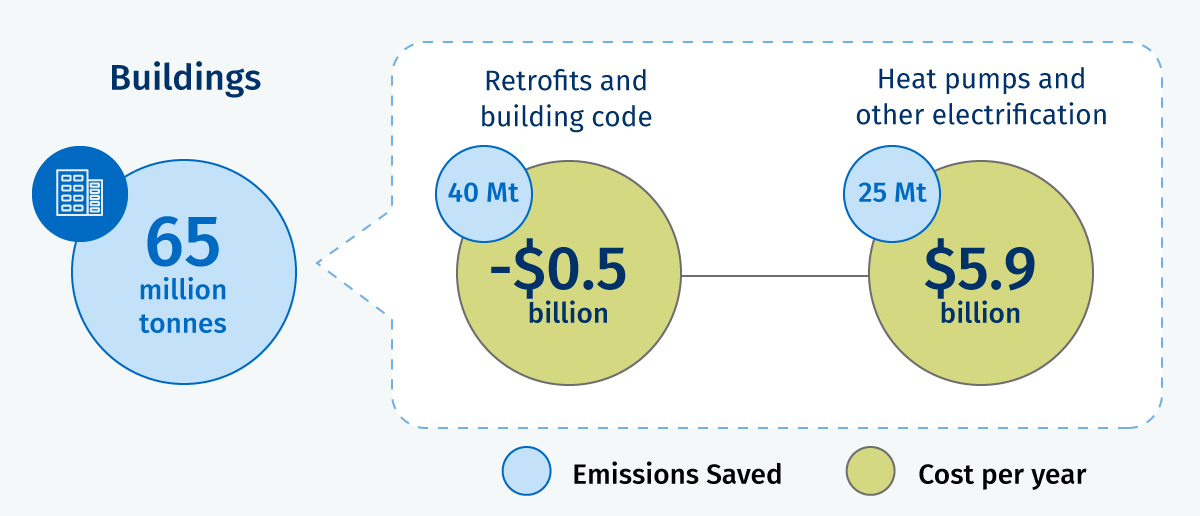

Costs to meet the 2050 goal

The costs of installing the most efficient insulation and electrical capacity are lower during construction than when retrofitting existing homes. For instance, the costs for heat pumps, in the absence of other retrofits, are nearly double for old houses than new builds.8

The upfront costs for a national Net Zero buildings plan would add 8% to the average construction bill, according to a joint study by the Canada Green Building Council and WSP9—but the upgrades would roughly pay for themselves in energy savings over the buildings’ lifetime. Finding ways to make the returns accrue more quickly, or spread costs over the life of the equipment (for example, with lower electricity rates for those who slash emissions) could accelerate adoption.

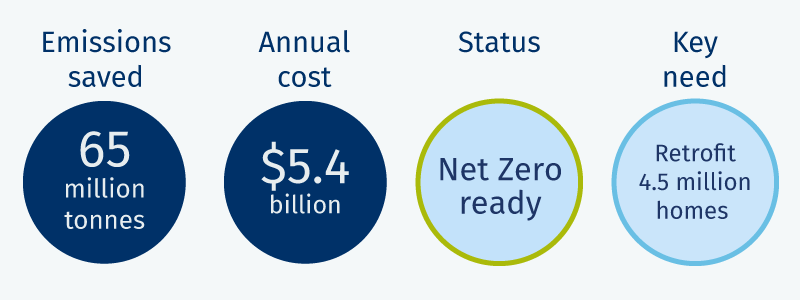

The added annual costs to bring both residential and commercial buildings to Net Zero could be about $5.4 billion a year.

BrainBox AI uses deep learning and algorithms to optimize HVAC systems, cutting energy waste in commercial buildings. Unlike current HVAC systems, which are reactive, its technology uses data to predict future temperature states and respond accordingly. The Montreal-based company was on Time’s list of the “Best Inventions of 2020,” and its technology—whose heart is a one-square-foot box—is already installed in more than 100 million square feet of real estate. BrainBox’s software is unique, but it does have some formidable rivals in the building sensor and automation space, including giants like Amazon and Google.

Enwave’s Deep Lake Water Cooling system is the largest geothermal cooling system in the world, using the cold waters of Lake Ontario to cool offices, hospitals and other buildings in Toronto’s downtown core. It’s got winter covered too, recovering wasted heat from buildings to provide low-carbon warmth. Enwave’s system reduces electricity consumption by 90% when compared to traditional sources. After water is used for cooling it is forwarded to treatment facilities for subsequent use in taps and showers. Enwave is expected to benefit from the growing popularity of district energy systems. But they aren’t always an option: cooling systems like Enwave’s require large and deep quantities of water, and they are capital- and labour-intensive to build.

![]()

Nothing reminds Canadians of the Net Zero challenge more than the cars, trucks and planes we rely on to navigate our vast country. And our own preferences may be as powerful as any technology. Over the past 10 years, SUVs accounted for 40% of new vehicle registrations, and pickup trucks drove another 20%.

Transportation is Canada’s biggest emitter after the oil and gas sector, adding 186 million tons of GHGs to the atmosphere in 2019. Passenger transport accounts for just over half of those emissions, but we estimate the percentage from moving freight has been growing three times as quickly since 2005.

Even with Canadians driving more and buying bigger vehicles, transportation emissions have been slowly declining. That’s in part to increasing fuel-efficiency standards and the introduction of electric and hybrid vehicles. EV sales are a small but growing share of the market, spurred mostly by government subsidies and enthusiasm from early adopters.

We need to work on making passenger EVs more mainstream. Hybrids and EVs made up only 3.5% of new light vehicle registrations last year, compared with 75% of new sales in Norway, where EVs are exempt from registration fees as well as much higher value-added and import taxes. In Canada, mid-range EVs cost $8,000-10,000 more than regular cars, over the span of seven years, entirely because of higher sticker prices. Policy changes, including federal proposals to ban sales of new gas-powered passenger vehicles by 2035, will spur domestic uptake and, presumably, cut those prices. Meanwhile, Canada is also set to benefit from significant investment by automakers into more varied EVs over the next decade.

Battery technology continues to progress, and prices have fallen 80% since 201310. That’s yet more evidence that deploying technology leads to economies of scale and innovation. If we can continue this trend, EVs may only be a few years from cost parity with gas cars which would cut the added costs of transition.

Battery-powered electric motors are the most practical low-carbon alternative to internal-combustion engines, but work best in light-duty vehicles that need to move short distances without frequent recharging. They’re too heavy and inefficient for bigger vehicles, and currently out of reach for jets. As for ships, batteries are slightly more practical for smaller vessels like local ferries, but still not able to carry large loads over long distances.

Canada’s climate poses unique challenges, too. Battery performance is weaker in the cold, so during prolonged winters EVs need to charge more frequently. That’s of little concern for daily commutes, but poses a greater challenge for extended road-trips and long freight journeys. Ultimately, infrastructure and some behaviour change will be needed, along with new battery chemistry.

Alternative fuels as a stop-gap measure

For now, heavy-duty trucks, ships and planes will need to depend on biofuels to reduce emissions. These fuels, which are generally made from plant and animal materials called biomass, have an emissions profile that can be about 80% lower than traditional fossil fuels. Most biofuels can’t entirely replace fossil fuel in existing engines: they have to be blended with varying amounts of traditional fuel to avoid engine problems. One example is sustainable aviation fuel (SAF), which is generally blended 50-50 with regular jet fuel.

More advanced biofuels with the same chemical makeup as regular diesel also exist, and can be used as full replacements. The scale of use is very limited so far and production can be restricted since these fuels are sometimes made from waste-food oils and crop residues that aren’t always readily available. Growing more plants to produce biofuels also has implications: we may end up with less land to grow food. And depending where the new cultivation occurs, we might destroy stable carbon sinks like forests.

Hydrogen fuel cells, which power electric motors with the energy carried in liquid hydrogen, could be useful for heavy transport further down the road. Many are hopeful the technology could one day transform the transportation sector. For the moment, though, there’s little infrastructure to support the technology, nor are trucks being built at scale with these engines.

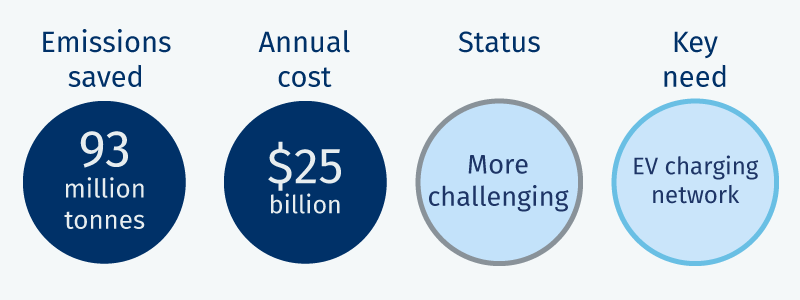

What are the costs?

Where electrification is viable, Canada can achieve deep emission cuts if it provides subsidies and invests in infrastructure to encourage EV use. That could be expensive. Based on current EV models and the average time Canadians own new cars, the government would conceivably have to provide EV subsidies of at least $300 for each tonne of GHGs saved to make EVs as affordable as gas-powered cars. That adds up to an annual cost of about $20 billion. Advancing battery technology—about one-third the cost of an EV—will go a long way in cutting that cost. Better infrastructure might make people more comfortable with carrying around smaller, cheaper batteries.

Where electrification of transportation is not viable right now, biofuels could fill the gap. But many applications are expensive: SAF costs about five times more than jet fuel, and could amount to $500 a tonne. Even if we could produce enough SAF to use in every flight, it could raise airline costs by as much as 50%.

The government expects current efforts to bring transportation emissions down by about 35 megatonnes. If an extra $25 billion were to be invested by Canadians on current technologies each year, a further 93 megatonnes of the projected 2030 emissions in the transportation sector could be eliminated on the path to Net Zero. But we’ll need more research and development to find better solutions for the rest of our emissions challenges.

Heavy-duty trucks rely on biofuels to reduce emissions, since batteries are too heavy. Ottawa-based GBatteries‘ ultra-fast charging technology could allow trucks to carry fewer batteries by recharging as quickly as it takes to refuel a tank of gas. What’s more, the company says its technology avoids a problem common to fast charging: battery degradation. Rival startups from Israel to Australia are looking to bring fast-charging solutions to market. While competitors are focused on new materials and construction of lithium-ion batteries, Gbatteries relies on a patented algorithm for fast charging. Listen to our conversation with GBatteries’ CEO Kostyantyn Khomutov on Disruptors.

Li-Cycle of Mississauga, Ont. has grown to be the largest lithium-ion battery recycler in North America in just five years. The company says its proprietary recycling process recovers 95% of the metals critical to battery manufacturing—much more than rival technologies do—saving those metals from ending up in a landfill. The materials can then be reused in new batteries. Li-Cycle’s process also produces no wastewater and emits less carbon than traditional recycling methods. One of its biggest challenges is preparing for wider EV adoption.

![]()

Oil and gas producers are not Canada’s only heavy emitters. The workhorses of the economy (mining and cement production, to name just two) require tremendous amounts of heat and energy, and emit a lot of carbon as a result. Their production is essential to everyday life, and to Canada’s economic well-being, accounting for 16% of exports in the last five years. Some parts of this sector have made tremendous progress since the 1990s, due to cleaner manufacturing processes. But with global demand for low-carbon materials growing, getting those producers to cut emissions even more will be crucial.

In recent years, Canada’s strategy to cut the emissions of heavy industry has focused on various levies like the carbon tax, with a preference for gradual increases rather than abrupt measures.11 Progress has been slow. One reason: most companies still use relatively inexpensive fossil fuels. For instance, it takes about 900 tons of steel to make a 5 MW wind turbine,12 and producing that much steel creates about 2,400 tonnes of CO2 emissions.13 The technology to easily substitute electricity or another fuel in that process would be far more expensive or perhaps not even commercially viable.

What’s more, many industries generate emissions as an inherent part of production. Making fertilizer ammonia, for example, is energy-intensive, and further generates greenhouse gases when the constituent ingredient hydrogen is extracted from natural gas. Or in the case of cement, breaking down limestone requires a chemical reaction that emits CO2. These inherent “process” emissions are the reason why carbon capture is likely to be needed in certain circumstances.

Making steel green

Traditional steelmaking involves melting high-grade coal with iron ore at very high temperatures in furnaces fired with fossil fuels—generating a lot of emissions.

A key challenge: how to make all the new steel we need for solar panels and other green technology with as few emissions as possible. The race is on to solve that problem in places like Sweden, where the first shipment of “green” steel was received this summer. That pilot project, like others in various stages of development, uses a process that replaces the coal in the first step of steelmaking with hydrogen. The transformational power of green steelmaking will depend largely on how cost- and emissions-effective hydrogen and electricity become in the decades ahead.

The federal government expects that a slowly rising price on industrial emissions and subsidies for cleaner processes over the next decade will only coax companies to eliminate 16 of the 77 megatonnes of greenhouse gases generated in 2019. With more policy changes and more investment, faster progress may be achieved to encourage the adoption of existing technology. Industrial heat pumps, for instance, and even regular electrical heat can replace fossil fuels in some low- and medium- temperature applications, such as parts of paper production. Carbon capture works well for concentrated exhaust streams, like those from fertilizer plants and, while costly, can be applied to more expensive cases like cement plants.

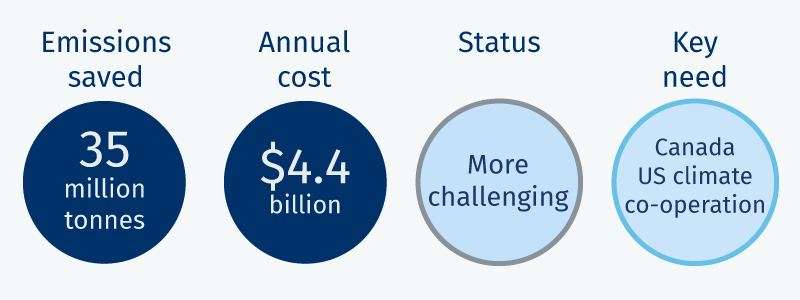

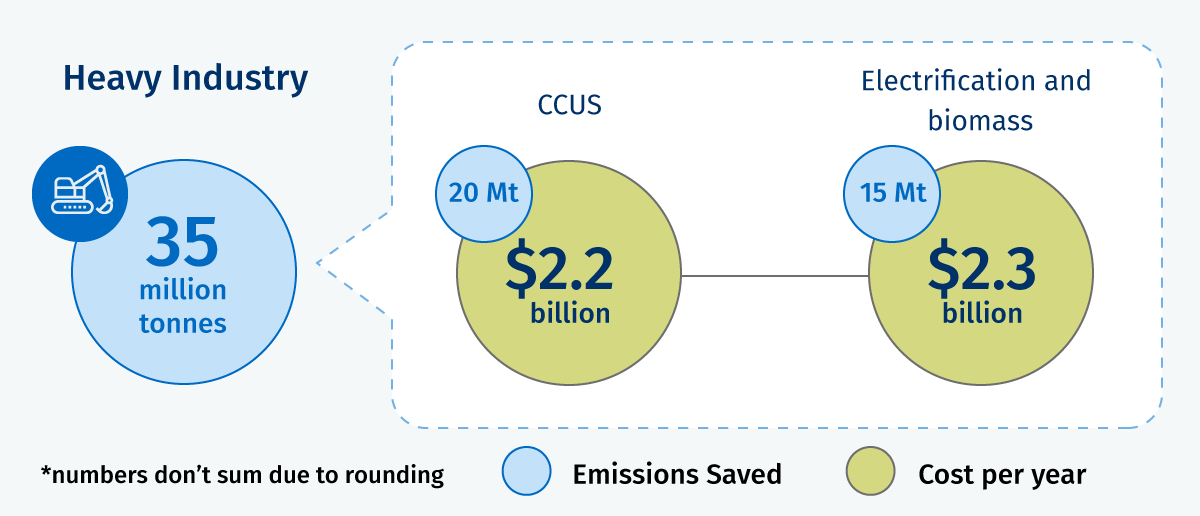

If an extra $4.4 billion were invested annually by industry and government on current technologies, a further 35 megatonnes of projected 2030 emissions in heavy industry could be eliminated on the path to Net Zero.

Dartmouth, N.S-based CarbonCure injects captured CO2 into concrete to make it greener. Its technology could help the heavy-emitting buildings sector get to Net Zero faster, and the amount of concrete being produced with its technology is doubling every year. That helps explain why CarbonCure attracted funding from Bill Gates’ Breakthrough Energy Ventures, Amazon and other big investors. Governments and municipalities are major buyers of concrete, so the company’s growth would benefit from procurement policies that encourage low-carbon concrete. Listen to our conversation with CarbonCure’s Rob Niven and Jennifer Wagner on Disruptors.

MineSense Technologies of Vancouver helps mining companies balance the need for sustainability with finding high-grade ore. Its ShovelSense technology, which can be retrofitted onto existing mining equipment, uses sensors and a proprietary algorithm to assess ore as it’s being mined, improving ore recovery and reducing waste. MineSense’s technology is being used in mines in Canada, Chile and Peru. COVID restricted its access to the mine sites of customers, forcing it to pivot to remote technology installations.

![]()

Canada is an agricultural giant, exporting wheat, barley, pulses and other food products to the world. The sector accounted for 2% of Canada’s total GDP and about 5% of its exports over the last decade and employs over 300,000 Canadians. It also generates about 10% of Canadian GHGs, or the equivalent of 73 megatonnes. Reducing them won’t be easy. Cows, pigs and other ruminant animals generate methane through their digestion, so the gases they emit are hard to trap. Widely used nitrogen fertilizers are necessary to improve yields but are a major source of nitrous oxide emissions. Like methane, nitrous oxide has a stronger warming impact than CO2.

While the amount of energy used to produce food per dollar of production has fallen, rising production has dwarfed efficiency gains. The amount of energy used in agriculture grew 30% between 2008 and 2018, largely in the form of diesel for more heavy machinery.14

The good news is that Canada compares well on agricultural emissions globally. In the livestock sector, for instance, the country ranks among the least carbon intensive, according to the Organization for Economic Co-operation and Development.

One reason for uneven progress on the farm: emissions from animals and land (including those after fertilizer application) aren’t subject to carbon pricing, and farmers are exempt from federal fuel charges on the diesel used to power equipment. The exemptions exist largely because carbon-mitigation efforts would be expected to raise food prices and put Canadian exporters at a disadvantage to global trading partners who don’t regulate farming as much.

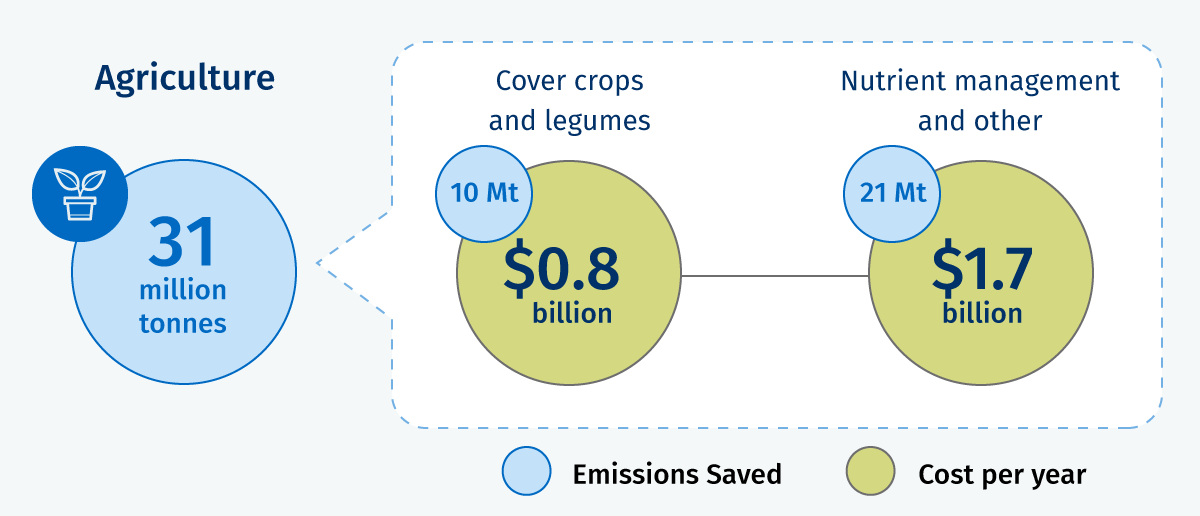

Changing the way we grow things—such as applying less fertilizer—would help. Farmers could be encouraged to plant more cover crops, which are sown after cash crops have been harvested to help reduce soil compaction and prevent erosion. Cover crops can also sequester more carbon in the soil and prevent leftover nitrogen from wafting into the atmosphere.

Rethinking livestock production and manure management could yield the biggest reductions. Indoor facilities can be modified to capture some methane and turn it into biogas. The same could be done for manure storage, another source of methane from livestock. This is already happening, on a small scale. Also, more selective breeding and changing animals’ diets could somewhat mitigate the amount of methane ruminant animals generate in the first place.

Switching out of fossil fuels will help, too. As is the case in other buildings, fuel sources to heat or cool farm facilities can be switched over to electric heat pumps. Farm equipment, as yet, generally hasn’t been electrified, but advancements in battery technology could make that happen sooner. Electric tractors are starting to come to market, but not combines. In some cases, like grain dryers, electricity is more difficult and expensive with current technology, but still feasible.

It’s important to remember that, trees, plants and soils can store CO2. The the proliferation of food-growing in rural (or urban) settings also has the potential to sequester carbon, if managed right.

Doing a better job of managing our natural world might impact climate change just as dramatically as cleaning up heavily carbonized industries. A recent study by Nature United, funded in part by RBC Tech for Nature, found that protecting our land could prevent 30 million tonnes of GHGs from being released annually. Taking better care of Canada’s agricultural lands, forests, wetlands and grasslands could sequester 48 million tons of GHGs annually by 2030, or about 6% of current overall emissions. A large part of the approach involves changing the way we do things on the farm. Regenerative agriculture is a set of farming practices—like planting cover crops to manage soil quality—that leverage nature to address climate change. It aims to increase carbon sequestration in soils and includes benefits like making farms more drought resilient. Other practices, like planting trees between crops and on pastures, are promising too: Nature United estimates these efforts could sequester as many as 7 megatonnes by 2030, even if limited to areas where large machinery isn’t used.

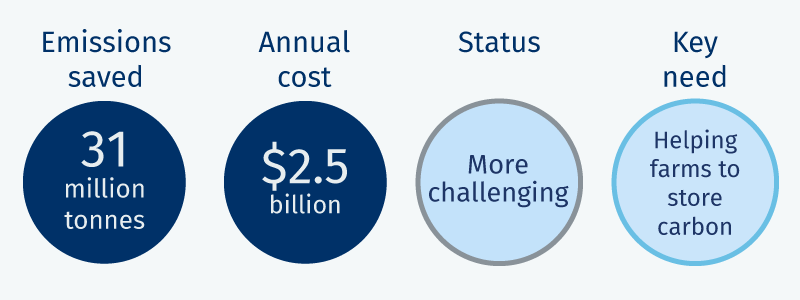

While some of these GHG reductions can be achieved at relatively low costs, most will be expensive and require new processes and capital investment. Comprehensive modelling of cover crops, for example, shows that about half this abatement will cost more than $50 a tonne, exceeding the current carbon price. We estimate cutting emissions in the sector to 43 megatonnes, from 73 megatonnes in 2019, could cost as much as $2.5 billion annually.

SemiosBio Technologies is a Vancouver-based precision farming platform. Its proprietary wireless network uses machine learning and artificial intelligence to provide farmers with a data-driven crop management solution. Its IoT network is the largest in agriculture, with more than 120 million acres under management and customers in countries from the U.S. and Australia to South Africa. The company has hundreds of rivals, but most are smaller and focused on one aspect of farming.

Another Vancouver firm, Terramera, is developing digital agronomy tools to support and scale the transition to regenerative agriculture practices. It’s also pursuing a remote sensing technology that can measure the carbon content of soil reliably and inexpensively—a move that could help lay the foundation for an agricultural carbon credit market. The company developed a proprietary chemistry technology, Actigate, to enhance the performance of organic inputs in farming and reduce the use of synthetic chemicals.

![]()

We’ve urged households to switch from gas cars and furnaces to EVs and heat pumps. But many can’t afford to take such steps. They can take inspiration from knowing that behavioural changes can make a big impact. For example, cutting waste from fruits, vegetables, and leftovers to levels closer to that of meat and dairy could reduce Canada’s emissions by up to 4 million tonnes.15 By changing how we move, how much we heat and cool spaces, and by using cement and other carbon-intensive materials more sparingly, we could cut emissions by as much as 1.7 billion tonnes globally by 2030, according to the International Energy Agency.16 The total represents more than 10% of the cuts we’d need in that timeframe.

The challenge is getting people to change. A low-carbon lifestyle can be more expensive, harder, and less convenient than the status quo. While getting nearly 40 million Canadians to accept less convenience in their daily lives is daunting, design and innovation could make things easier. To today’s youth, getting kicked off Youtube if their parents need to make a phone call is laughable. And the thought of working from home several times a week would have seemed daunting to professionals just two years ago. In 10 years, home cooks may covet induction stoves the way they currently admire gas ranges.

Every sector has a role in helping consumers make more informed and cleaner decisions. Here’s how we think we can get started:

- Businesses should inform consumers about how their choices impact emissions. Outlining the emissions impact of different package-shipping options, or the environmental cost of packaging, could affect consumer choices.

- Mandatory labelling for emissions-intensive decisions. We could require home-sellers to disclose energy efficiency ratings and annual emissions from homes, enabling buyers to compare houses on emissions and costs.

- Cheaper funding for greener options. The financial sector has long innovated in ways that have helped drive change. Securitization of retrofit loans or mortgages for green homes and offices could tap ESG markets and bring down costs, as they once did for mortgages more broadly.

- Making greener transit more enjoyable. Dark subways, crowded trains, and unprotected bike lanes do little to encourage city-dwellers to eschew cars. Adding amenities to stations and vehicles (Wi-Fi and shopping, for instance) could boost ridership. So could building safer infrastructure: bike lanes in Toronto, especially ones that increase safe access to workplaces, have encouraged many more cyclists.17 Mandating secure bicycle parking and e-bike charging at businesses and new condos could go a long way too.

- Re-jigging electricity pricing. Nudging consumers to use less electricity when it’s most expensive to produce is the logic behind time-of-use pricing in some provinces. Expanding that nationally is a good first step. Paying industry to slash demand during peaks could be even more effective.

![]()

For decades, we took a piecemeal approach to environmental regulation and to protecting the climate. The result: emissions rose anyway. Getting to Net Zero will require a bolder plan, teeing up changes for the coming decades.

In the preceding pages, we’ve outlined the pathways that such a plan could follow. It will require everyone—homeowners, business operators, scientists, skilled tradespeople, educators, city planners—to lean in. But in conclusion, we’d like to focus on the role that policymaking can play, with eight ideas to ignite change:

A national policy on electrification

Federal incentives will be needed to develop better links between provincial grids, harmonized regulations and coherent pricing. The goal: double production over the next 30 years. Producing more power cleanly will require some tough choices, even with a rising carbon price. We may need a lot more hydro-electric power, and transmission lines to get it to major centres. Nuclear options need to stay on the table. And we’ll require carbon capture for gas-fired plants, even as renewable options and batteries build commercial scale. What will be essential: greater interprovincial cooperation.

A national strategy for green skills

Clean innovation won’t succeed if there aren’t enough engineers to deploy carbon capture systems, or contractors to install heat pumps. The goal: train up to 200,000 new workers in green skills, and reskill 100,000 existing workers, by 2030. A federal Green Skills Grant could retrain existing employees, while provincial programs could support career shifts. Teachers will need course content on climate tech, as well as the new “green” skills for tomorrow’s workforce. And farmers will need to enhance their ability to monitor how well their soils are storing carbon from the atmosphere.

Long-term commitment to carbon pricing

Canada’s plan to increase the national carbon price, through 2030, should be reaffirmed by the federal government, provinces and major business groups, to signal to the world that it is a shared priority. Ottawa should also allocate a significant (and clearly defined) portion of the revenue to technology development and adoption, and study the economic impact and sufficiency of the price as it increases to $170 per tonne. Business and environmental groups need to help governments move forward in ways that benefit every region.

Leveraging climate to enhance U.S. trade

Canada should engage the U.S. in bilateral talks around climate policy, with a focus on strategic supply chains, energy products and emissions-reduction technologies. The two governments should explore a border carbon adjustment to be applied to heavily traded goods, to ensure North American products aren’t put at a disadvantage by explicit or implicit carbon prices. Of particular importance: a secure place for Canada in the rapidly growing EV supply chain, with special focus on battery technology and critical minerals. Research collaboration with the U.S. can also help.

An industrial strategy for carbon capture, utilization and storage

The federal government and major industrial-emitting provinces should agree to a new framework for CCUS – essentially, technologies to capture and store emissions in the ground or in new products – that includes research grants, long-term tax credits for carbon stored, and new approaches to public-private investment. Critical issues: clear rights to geologic storage, permits for CO2 pipelines and flexible, time-bound regulations. Importantly, Indigenous communities must play a leading role in this next chapter of Canadian energy.

A national action plan on sustainable agriculture

Agricultural emissions are inherent to our food system, since we’ll need nitrogen fertilizer as long as we grow crops, and will produce methane as long as we raise cows and pigs. There are ways to cut emissions from current levels without lowering food production, but pricing farm emissions can lead to unacceptably high food costs. A better option: allowing nature-based sequestration on farms — from cover crops and trees, for instance — to produce tradable carbon credits. To get there, farmers need access to more soil monitoring equipment, data systems and training.

Super-charging electric vehicles

EVs will be clear winners in the transition, but unless costs fall rapidly, their adoption may not move fast enough to move the larger dial. The pluses of EV ownership are currently offset by range anxiety, a lack of charging stations, and the perils of cold weather. EV infrastructure will help, as will vehicle mandates, including Ottawa’s proposal to allow the sale of only zero-emission vehicles by 2035. On the production side, Canada can do more to support North American battery supply chains, for instance by investing in refining capacity and domestic battery manufacturing.

Rapid retrofitting

Canada’s plan to retrofit more homes must be urgently accelerated. A good start: programs to help owners manage the disruptive process of rewiring or redesigning one’s home. Net Zero building codes can remove the need to retrofit recent builds. Other policies, including financing, can help homeowners tackle large projects collectively. A national retrofit strategy could also promote group retrofitting services, and support communities that want to rethink heating altogether, with centralized geothermal models, for instance. The need: retrofit 4.5 million homes by 2030.

Conclusion

This report lays out the case for accelerated climate action, with clear goals and significant opportunities. Despite the challenges, and perhaps late start, Net Zero is within reach.

To get there we will need to stretch our approach to capital mobilization and to regulatory flexibility. We will need to imagine new ways to assess opportunities and invest in them by harnessing public and private capital, coordinating federal and provincial authorities, and ensuring Indigenous communities help to lead the way.

Canadians want a faster, and more effective, response to the climate challenge and Canadian innovators have shown they can get it done. Canadian businesses, in a range of key sectors, are driving their own transitions. The payoff – environmental, economic and social – is there if we start to move collectively.

If we get it right, we can usher in a new era of ingenuity that will protect and enhance the environment, strengthen existing industries, create new ones, and extend prosperity’s reach to millions more Canadians.

For more, go to rbc.com/climate.

Download the Report

1. https://www.science.org/doi/10.1126/sciadv.abd6034

2. https://www.nrcan.gc.ca/sites/www.nrcan.gc.ca/files/canmetenergy/pdf/fichier/81770/

windtrm_resource_map.pdf

3. https://canwea.ca/wp-content/uploads/2016/07/pcwis-fullreport.pdf

4. https://www.lazard.com/media/451419/lazards-levelized-cost-of-energy-version-140.pdf; https://www.lazard.com/media/451566/lazards-levelized-cost-of-storage-version-60-vf2.pdf

5. https://www.nature.com/articles/s41467-020-14555-y

6. Canada had 35.2 GW of fossil-based electrical capacity in 2018 (CER, 2020). The fastest growing battery-storage market, California, will add 1,750 MW of battery capacity in 2021. If Canada installed a similar amount of battery storage, it would take 20 years to replace fossil capacity.

7. https://www.toronto.ca/legdocs/mmis/2018/pe/bgrd/backgroundfile-114375.pdf

8. https://www.oeb.ca/sites/default/files/OEB_MACC%20Report_20170720.pdf

9. https://www.cagbc.org/CAGBC/Advocacy/making_the_case_for_building_to_zero_carbon_2019.aspx

10. https://about.bnef.com/blog/battery-pack-prices-cited-below-100-kwh-for-the-first-time-in-2020-while-market-average-sits-at-137-kwh/

11. Heavy industries are not subject to the fuel charge, but rather are covered by provincial and federal regulations that limit the level of emissions by each facility, and charge the carbon price on a subset of their emissions.

12. http://vaclavsmil.com/wp-content/uploads/15.WINDTURBINE.pdf

13. RBC calculations

14. https://oee.nrcan.gc.ca/corporate/statistics/neud/dpa/showTable.cfm?type=CP§or=agr&juris=ca&rn=1&page=3

15. National Zero Waste Council, RBC calculations (https://lovefoodhatewaste.ca/about/food-waste/)

16. https://iea.blob.core.windows.net/assets/beceb956-0dcf-4d73-89fe-1310e3046d68/NetZeroby2050-ARoadmapfortheGlobalEnergySector_CORR.pdf

17. https://www.sciencedirect.com/science/article/abs/pii/S000145751930658X; https://www.utoronto.ca/news/why-don-t-more-torontonians-bike-work-u-t-study-points-disconnected-cycling-infrastructure

Contributors:

John Stackhouse, Senior Vice President

Colin Guldimann, Economist

Ben Richardson, Research Associate

Steven Frank, Consulting Editor

Darren Chow, Senior Manager, Digital Media

Carolyn King, Senior Managing Editor

Farhad Panahov, Research Associate

This article is intended as general information only and is not to be relied upon as constituting legal, financial or other professional advice. A professional advisor should be consulted regarding your specific situation. Information presented is believed to be factual and up-to-date but we do not guarantee its accuracy and it should not be regarded as a complete analysis of the subjects discussed. All expressions of opinion reflect the judgment of the authors as of the date of publication and are subject to change. No endorsement of any third parties or their advice, opinions, information, products or services is expressly given or implied by Royal Bank of Canada or any of its affiliates.

Learn More

Learn More